Custom Kits Designed to Maximize the Efficiency of Your Manufacturing Process

Capabilities

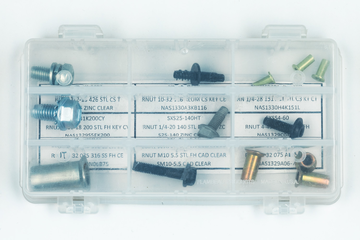

Custom kitting jobs range from simple to highly complex, with the ability to assemble 100+ parts per kit, build multiple sub-kits within a master kit, and even provide assembly services (e.g., applying grease to an O-ring and placing it on a bolt). The process includes state-of-the-art automated equipment for increased speed and accuracy. Customer-specific information can be printed directly on bags and other packaging, including:

- Customer-specific part numbers

- Customer-specific product description

- Customer logo

- Barcode

- Lot number

- Quality starts with inspection and verification of all components to customer requirements.

- Our quality services include controlled secure storage and electronic tracking of all components throughout the inspection, validation, kitting, and shipping processes.

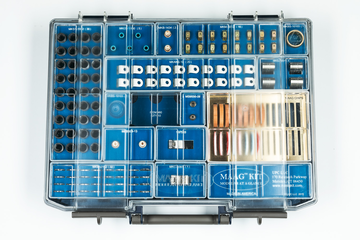

- Av-Tech provides the highest level of precision kitting in the industry, utilizing the MAAG Kit system.

Av-Tech Industries Final Inspection and Shipment of Kits

- Assembly and verification of kit configuration to BOM

- Final inspection to include FOD control

- Processing of test reports and certifications

- Source inspection of completed kits

- Security to prevent tampering until point of use

- Uploading of all required documentation to customer site

- Packaging and shipping of kits per customer requirements

Benefits and Features

- MAAG Kits increase productivity

- MAAG Kits reduce lost assembly time

- Delivery direct to point of use

- MAAG Kits contain all parts required for assembly

- Defect-free hardware

- Reduced FOD due to less handling by technician and greatly reduced packaging (bags and labels)

Benefits to Customer

- Lower procurement costs after initial ship set

- Lower production costs through time savings

- Reduced installation costs

- Reduce total inventory investment

- Turn around time is greatly reduced

- Kits are reusable for many ship sets

- Flexibility in revisions of kits (simple cell changes)

- Greatly reduced potential for packaging errors

- Reduced escapes due to FOD, quantities, and hardware damage

Best Practices

|

Multiple levels of verification to ensure quality and accuracy. Product undergoes three levels of quality testing (pre-production, 1st article, pre-shipment). Each completed kit is weight-verified, and samples from each lot are inspected prior to shipping. Customer-specific standard operating procedures are utilized when specified.

|

|